The main function of Geomagic Control X

Since Geomagic Control X is based on the success that 3D Systems has developed, the top-level measurement software for over 20 years is the most reliable in the world and can be used for a variety of purposes. As well as innovative functions that are important and easy to use in traceability as measurement software helps increase the production efficiency of the inspection process at the production site and quality control

1. Support reading hardware, industry standard and many files.

|

Supports various contactless and optical scanners used in industries and contact devices such as Portable read heads CATIA®, NX®, Creo®, Pro / ENGINEER®, SOLIDWORKS®, Solid Edge®, Autodesk Inventor®, support loading of important CAD file formats, such as some people can also read PMI and GD data. & T All CAD reading options can be used without additional costs. |

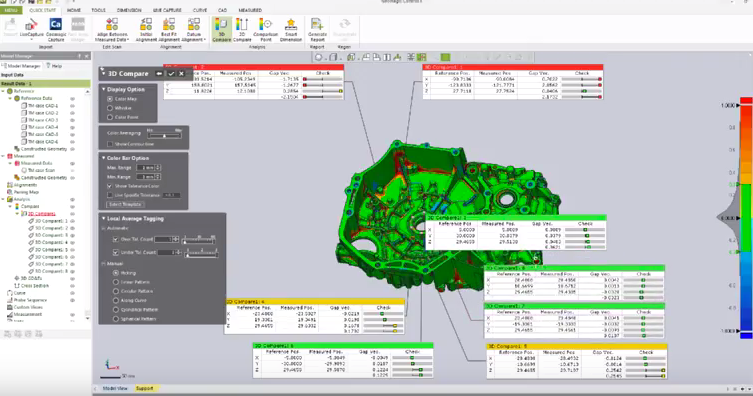

2. Intuitive interface designed for professionals.

|

The fully updated Geomagic Control X user interface will allow anyone to easily take advantage of a wide range of options, all with the precision of measuring and analyzing parts, regardless of usage. |

3. Processes that focus on workflows, function checks that increase performance and do not require initial setup.

|

Geomagic Control X provides a process that is easy to understand and easy to understand. In addition to following the predefined list, you can prove effectively without the hassle of using a computer and doing it quickly. |

4. Synchronization function for easier and automatic tasks

|

Geomagic Control X can be operated quickly, reliably and flexibly without being bound by steps. This task is automatically maintained as a history-based validation process that can be modified and can be applied to confirmation of modifications and checking the content of repeat options. |

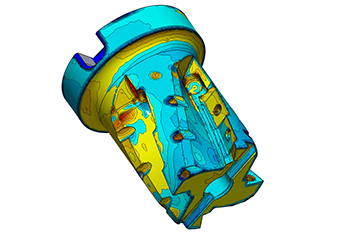

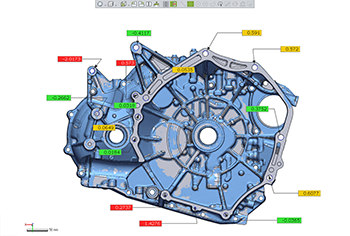

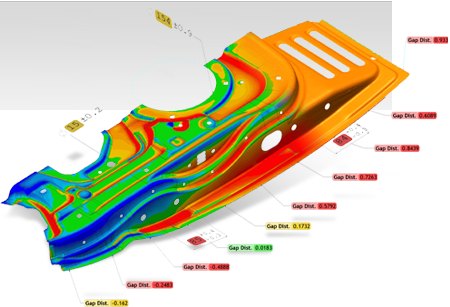

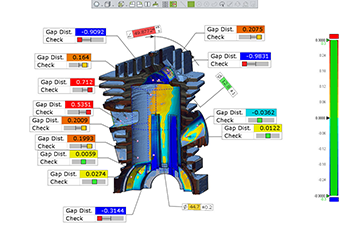

5. Measurement of the shape recognition of CAD, 3D drawing (PMI), size / geometric tolerance (GD&T)

|

Due to the ability to identify CAD shapes, it can be used intuitively to increase work efficiency. PMI evolution and GD & T help stakeholders in different positions to interpret the test results without differences. |

6. Comparative analysis of many results that are useful for reliable judgment

7. Report function that can be created flexibly.

8. LiveInspect ™ is effective for thorough examination.

|

|

Operating Environment

Manufacture's website : https://products.datadesign.co.jp/geomagic-cont/02_geomagiccontrolx_specification